What is Dry Wall Panel?

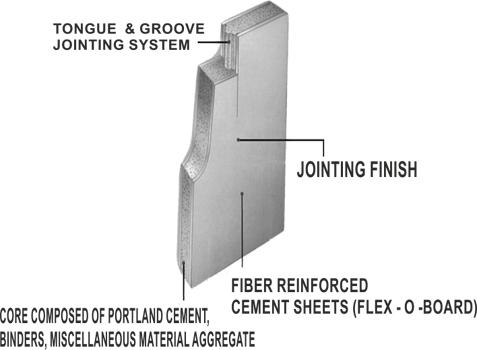

Ready-to-install Panels is poised to revolutionise building construction, taking it to a whole new level. They are sandwich panels, made of two Fibre Reinforced Cement facing sheets, on either sides of a lightweight concrete core. The core is made from a mix of Portland cement, binders, and silicaceous and micaceous material aggregate.

Apart from being fully cured at the factory itself, panels have a tongue and groove jointing system that facilitates rapid construction with minimum effort.

Light-weight, Water-resistant, Fire-resistant, Termite-resistant, Strong and Durable, Sound Insulation, Space Saving, Eco-friendly.

Dry Wall Panels is an ideal solution for dry walls and partitions. This innovative green product, certified by the IGBC and GRIHA, stems from our commitment to create greener buildings, for a greener planet.

BENEFITS

Light-weight

Allows easy handlings & erections at larger heights. Due to light in weight, the dead load on the structure reduces & hence we can save on cost of structure

Strong and Durable

Aerocon Panels are manufactured from high quality materials imparting adequate strength & long life. Cement based product as good as other conventional materials.

Water-resistant

Aerocon Panels are having excellent Water resistance properties.

Fire-resistant

Aerocon Panels are having excellent Fire resistance properties.

Termite-resistant

Aerocon Panels are having excellent Termite resistance properties.

Sound and thermal Insulation

Aerated panels provide high sound & thermal insulation properties.

Space Saving

Due to slim in thickness, it provides additional usable floor space /carpet area comparing to conventional walls.

Eco-friendly

Usage of recyclable material- Eco Friendly & one of the Green Building Material.

What are Aerocon Panels?

A sandwich panel of two fiber-reinforced cement sheets enclosing a light weight concrete core composed of Portland cement and Fly-ash

Fully cured at factory, they are ready for installation right away

Unique “Tongue and Groove” jointing system facilitates rapid construction with minimum effort

10-20 times faster to construct

Tongue & Groove jointing mechanism/system allows you faster construction. No cement, sand & curing required at the site. Factory Pre cured readymade wall for dry wall constructions

Features and benefits

Savings

Cost: Light-weight, therefore results in structural savings up to 20% Time: 10-20 times faster to construct Labour: Pre-cured and ready-to-use, therefore eliminates on-site curing

Space

Thinner walls: Provides additional carpet area, up to 5%

Strength

Long-lasting: Cement-based panels High axial compression and bending strength:Can build load-bearing structures

Sustainable

Save resources: Cement and sand are not required Reusable: The unique tongue & groove joint makes it easy to uninstall Eco-friendly: Use of fly ash

Safe

Fire: Highly resistant Weather: Can withstand adverse conditions Termite and water-resistant: Doesn’t permit the growth of bacteria and fungus Toxic emissions: None

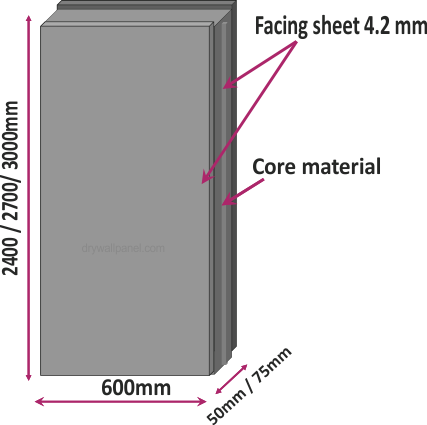

Dimension of AAC Blocks

Standard width

Aerocon Panels are available in a standard width of 600mm

Varying Thicknesses

50 and 75mm

Lengths

2400, 2700, 3000mm

Applications of Aerocon Panels

Partition

Full Height Partition Half Height Free Standing

Prefab Structures

Roofing

Mezzanine flooring

Technical Specification

| Properties | Unit | Thickness | Remarks | |

|---|---|---|---|---|

| 50mm | 75mm | |||

| Weight (nom) | Kg/m2 | 39 | 54 | Nominal weight@ |

| Bending test (4 point UDL) uniformly distributed load 2.9m span | Kg/m2 | 66 | 95 | Factor of safety–2.5 |

| Bending test (4 point UDL) uniformly distributed load 1.5m span | Kg/m2 | 198 | 265 | Factor of safety–2.5 |

| Flexural strength/modulus of rupture | Kg/cm2 | 67 | 58 | Typical test results |

| Thermal conductivity | W/m-k | 0.22 | 0.21 | BS 4370-Part 2 |

| Sound transmission co-efficient (Typical test results of Prasar Bharati and National Physical Laboratories) |

db | 33 | 36 | IS:9901(PartIII)–1981 IS:11050(PartI)–1981 |

| Fire rating* | minutes | 60 | 120 | BS 476 Part 20-22 |

| Surface spread of flame* | Class I | BS 476 Part7–1971 | ||

| Fire propagation index (I)* | I | 3.7 | BS 476 Part6–1981 | |

| Ignitability* | (Kgs) | Class ‘P’ | BS 476 Part5–1968 | |

| Note: The above specifications are based on typical test results of Panels with Flex-o-Board, and are subject to revision. *As per test results of CBRI, Roorkee. @ Could vary due to change in moisture content |

||||